New sculpture opens opportunity for students to leave lasting mark at DHS

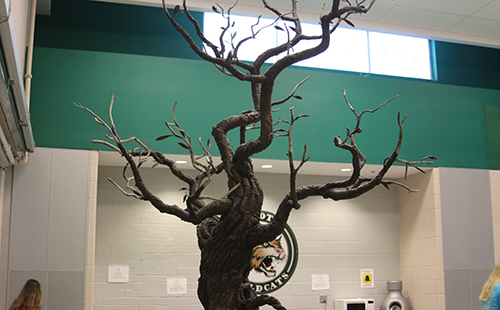

The Tree of Excellence, created by art teacher Tim Mispagel, resides in the Union with the purpose of recognizing outstanding students.

When students walked in De Soto High School at the beginning of the school year, a new addition to the Union could be seen. The bronze tree which has been sitting in the union since August was recently put into place and finally finished.

While many students know that the sculpture was created by art teacher Tim Mispagel, it may be more of a surprise to find out about the opportunity for student engagement that comes along with the tree.

The “Tree of Excellence” was made with the purpose of recognizing students that are outstanding in different ways, whether it be through grades, attendance, extracurricular activities, community service or more.

“The idea is that the students would make it onto the Tree of Excellence,” Mispagel said. “There’s a name plate that would be on there that would be added to the base of the tree.”

There is no set number of how many students per graduating class will make it onto the tree, but a point system is being considered to measure student achievement.

The Tree of Excellence’s involvement in student activities does not stop at just recognizing exceptional seniors. There is the opportunity for other classes to be able to work on the name plates that would be added to the sculpture.

“What we’re talking about is 3D printing [the name plates] because we can customize each name plate, and we can do that in house, which wouldn’t be a cost to the school,” Mispagel said. “We’ll have a format that the Emerging Technologies class would type into Adobe Illustrator, extrude that and 3D print it into a name plate.”

The idea for the Tree of Excellence started when Mispagel made a similar sculpture for a company called Teva.

“The original concept of the tree was called the ‘Tree of Life,’ and I was commissioned by Teva to make this tree for the lobby of their building,” Mispagel said. “Teva, which is a company based out of Tel Aviv, Israel, has a lot of history with the olive tree in the Middle East, because it’s an arid climate and the olive tree has some of the deepest roots. That tree throws its roots deeper than most trees so it can find a water source and still produce fruit.”

Former Principal Dustin Mortenson approached Mispagel with the idea of making a tree sculpture for DHS.

“He [Mortenson] found out that I had done the project,” Mispagel said. “We had just completed the new addition. Mr. Mortenson thought it would be a cool idea to put it into the Union and came up with the idea of the Tree of Excellence and recognizing students for living the values as a wildcat.”

Since Mispagel had completed the tree for Teva, the process for DHS’s version of the tree was more convenient.

“Because I already had the mold for it, I was able to save a little bit of cost with the foundry,” Mispagel said. “I didn’t have to remake the tree; I just had to put the wax back in the molds. It took me a year to do that.”

Although the Tree of Excellence comes from the mold of the Teva tree, the DHS sculpture is still one-of-a-kind.

“The unique thing is if you took our tree and put it next to the Teva tree, they would look different,” Mispagel said. “The orientation of the limbs and things like that are a little bit different, so each time I were to cast this piece, it would be a unique sculpture. No two would ever be exactly the same.”

When sculpting the Teva tree, Mispagel started with oil-based clay and a wire mesh. After shaping it and gluing it together, he melted the clay and brushed it on over the mesh like a wax before drawing into it to add details.

Once it was sculpted, Mispagel brushed polyurethane rubber to make the “mother mold,” which holds the polyurethane in shape so that wax can be added inside of the mold.

Mispagel turned to Ad Astra Bronze Art in Lawrence to handle the shell, bronze and welding.

“Once the wax goes inside the mold, that’s what the foundry needs,” Mispagel said.

The foundry then made another mold of the wax made out of a refractory shell before dipping it into a clay slurry. After putting on a thicker shell, they then put it in an open-bottom kiln, where the inside wax melted out of the shell, leaving the negative for the molten bronze.

Ultimately, the tree was done in “30 or 40” pieces that had to be welded together to create the sculpture.

The entire process took Mispagel about a year and a half to complete.

The Tree of Excellence provides a unique way to allow students to leave their mark at DHS.

Meet Abby Smith, the Green Pride's first Graphic Design Editor. This is Abby’s senior year, as well as her third year on staff. She has...